|

While MCL does not own any technology or

process patents, MCL is proud of its current strength and capabilities in the following

areas.

| PIONEER PROCESS DEVELOPMENT

| With exceptional strength in process

engineering, MCL is very capable of assisting clients to develop pioneer process concepts

into commercial scale plants. |

|

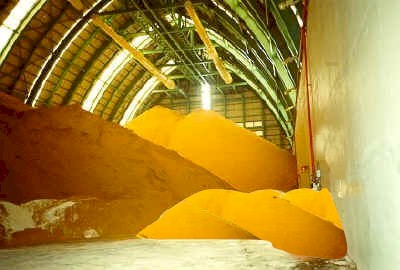

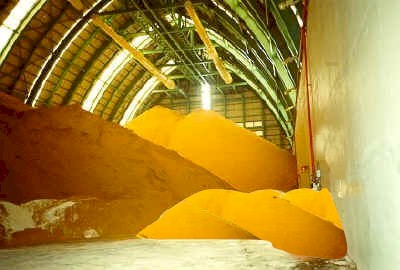

| SUGAR REFINING

| MCL has completed the process and detailed

design of a US$150 million, 1,200 MT/day cane sugar refinery project in Taiwan, on which

MCL is responsible for the sugar refining process development, optimization, design and

guarantees. |

|

| PROCESS MODELLING & SIMULATION

| MCL has developed a dynamic computer model

and simulation for the Taiwanese sugar refinery project, which proved to be most useful

for the purposes of process stability check, process optimization, plant automation check,

and client personnel training. MCL is currently developing a computer model for a generic

sugar refinery for general application. |

|

| PROCESS/PLANT AUTOMATION

| MCL's combined strength in process control

and instrumentation yields its exceptional strength in process and plant automation.

| MCL was responsible for the design of the

first three fully automated natural gas dispensing units for automobiles in Canada. |

| MCL is currently completing the design of

the world's most automated cane sugar refinery in Taiwan, requiring only 5 operators per

shift. |

|

|

| PROCESS HAZARD ANALYSIS

| With its affiliate, CHI, MCL is proud of its

capabilities and experience in the field of Process Hazard Analysis. |

|

|